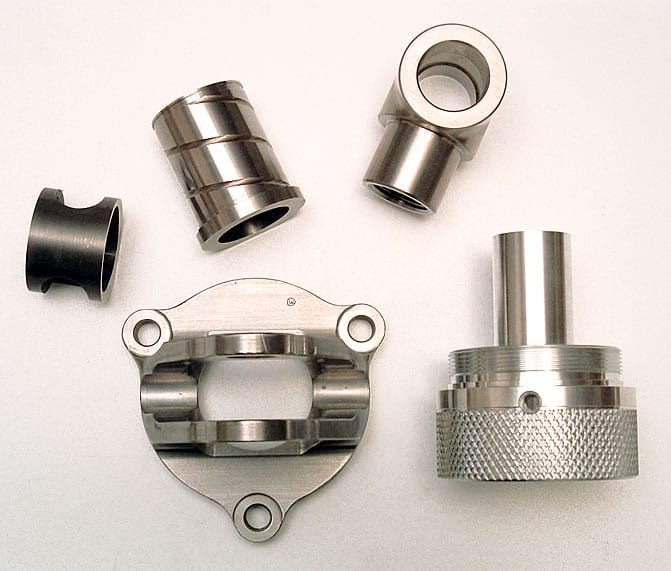

Sub-contract CNC machining has been our most successful avenue over the past decade. We started out machining components for our own Golf Business before diversifying into sub-contract CNC Machining and now service such markets as:

- Sport & Leisure

- Defence Industry

- Sub Sea

- Motor Sport

- Medical

- Lighting

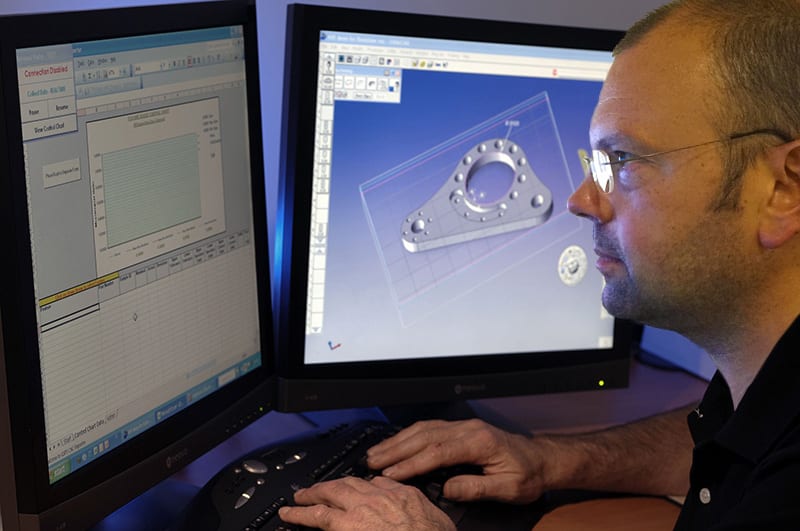

Our focus has always been to provide the customer with the product they require via the most cost-effective means. This can be simply via producing components using the most up to date on-line and off-line technologies, or by addressing design requirements and delivering solutions to our customers’ satisfaction.

The CNC Department can call on:

- A Highly Skilled Workforce

- Solidworks 3-D Modelling

- Offline Programming

- CNC Turning

- CNC Milling

- Fully Equipped Inspection Dept

- Conventional Turning & Milling

- Tooling Capabilities

Our CNC Machinery includes:

Lathes:

- Mazak 250MSY Twin Spindle (x2)

- Mazak 200M

- Mazak 350M

- Citizen L32 Sliding Head 7-Axis Twin Spindle

- Cincinnati Hawk 150

Milling Machines:

- Mazak 410 4-Axis (x2)

- Mazak VTC 300

- Mazak VTC 200

- Cincinnati Dart 500

In addition, our achievement of ISO9001 Quality Standard has rubber stamped our dedication to producing quality products. The quality system is operated by all the staff at Standel Dawman Ltd from the Directors to the shop floor technicians, producing high precision components.

Post Processing

We are able to accommodate a wide variety of finishing to our machined components, with a lot of experience in:

- Anodising

- Powder Coating

- Chroming

….to name but a few!!

Like what you see? Get in touch to discuss your requirements.

We are committed to a policy of Quality Assurance which is designed to ensure that our production of Precision Machined Components comply with customer requirements and expectations.